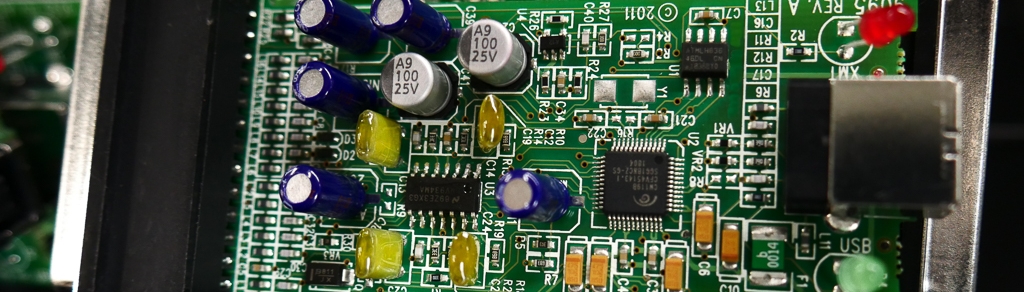

THD (Thru-Hole Device)

SMT (Surface-Mount Technology)

SMT & THD mixed Technology

2 sided SMT and THD assembly

Quantities: 1 – 10,000 PCBs per month

Passives parts: Size 0402 and larger

IC Devices: QFP Leaded devices, Leadless devices including BGA, UBGA and QFN’s

Connectors and terminals: SMT or THD

Component Package Includes: Reels, Cut tape, Tube, tray and loose and bulk parts

PCB’s Largest: 15″ x 15″

Shape of PCBs: Rectangular, Round, Slots, Complex and boards with Cutouts.

Type of PCBs: Rigid FR-4 and Rigid-Flex boards

Types of Assembly Process: Leaded and Lead-Free (RoHS)

File Format of PCB Design: Bill of Materials (.xls, .csv and .xlsx) and Centroid data file (Pick-N-Place/XY file)

Quick Turn PCB Assembly Services

Full Product Build

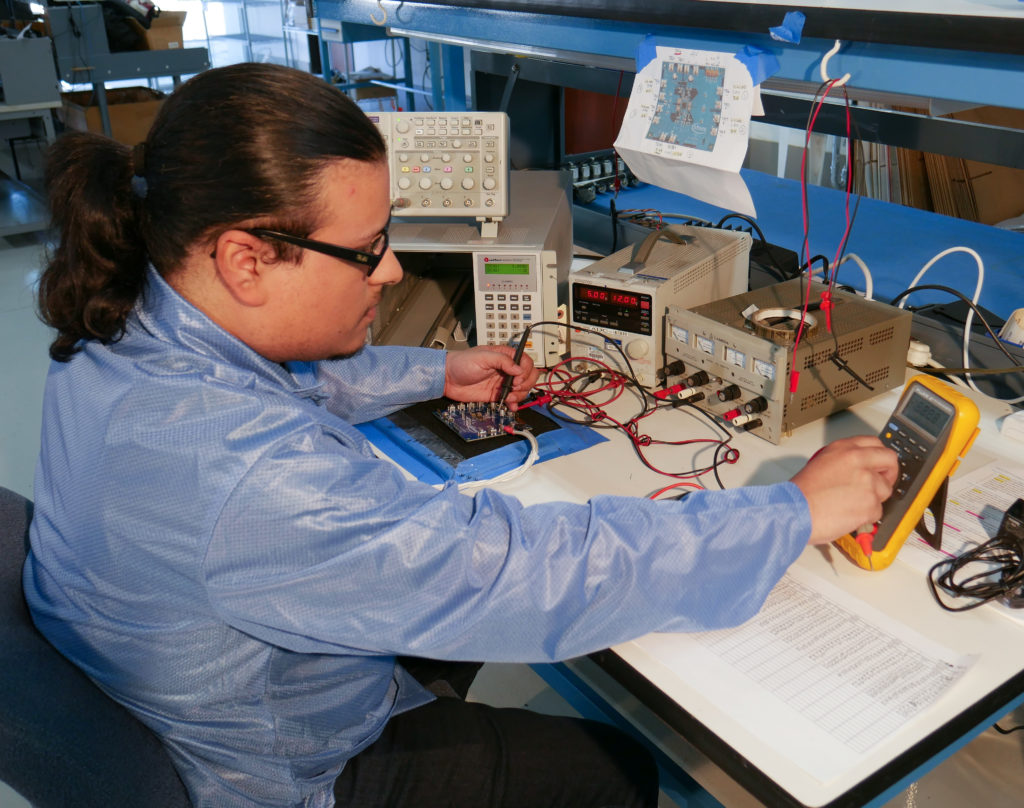

How We Inspect & Test Our PCB Assemblies

- Basic Quality Test: Visual inspection. IPC 610 Class 2 (IPC 610 Class 3 Customer Requested)

- X-ray Inspection: Tests for BGAs, QFN and bare PCBs.

- AOI Checks: Correct components, missing components and polarity.

- Functional Test: According to the customer’s testing procedure.

Equipment List

MPM Full Vision Automated Screen Printer

Manual Screen Printer

Amistar Placepro SMT Machines

Juki 760 Placement SMT Machines

Manix 8 Zone Convection Oven

Technical Devices Nu Era 16’ Flow Solder Machine (Leaded)

Solder Fountain (Leadfree)

Aoi Systems Scanspection AOI 1

Den-on RD-500V BGA Repair Station

Aqueous Technologies Batch Cleaners

Closed Loop DI System

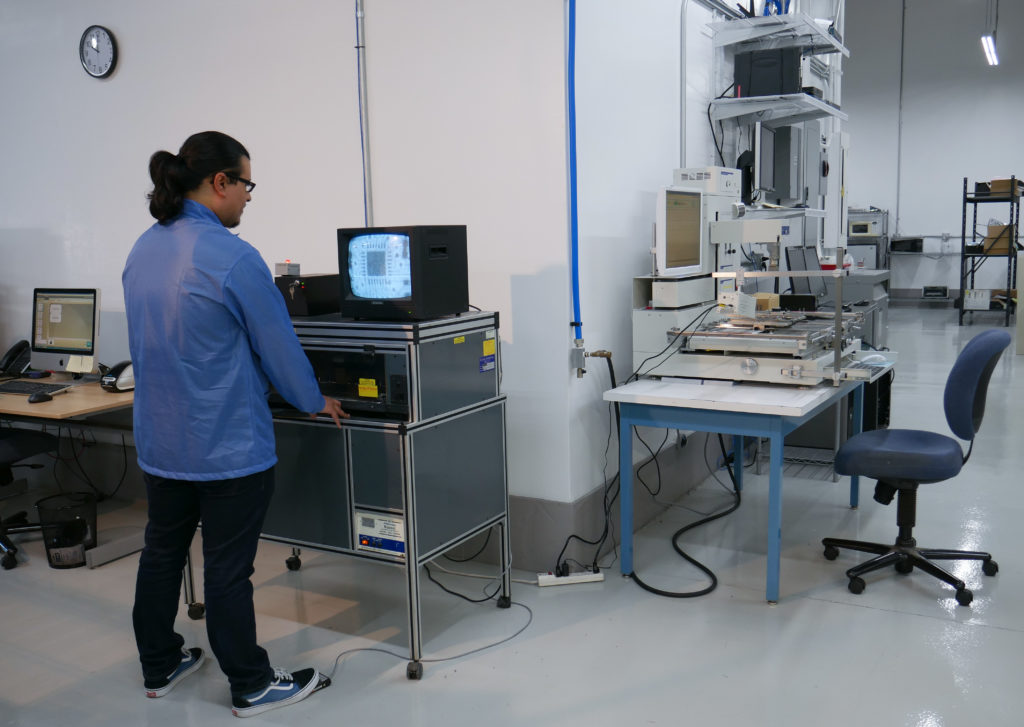

Matsunaga SVC 1000 X-ray

Hakko and Weller Solder \ Solder Touchup Stations with Microscopes